The Bravearm MMX is an automatic cutting system dedicated to the processing of rolled fabrics, perfectly suitable for the production of sails for boating as well as for cutting PVC fabric panels for roofing and tensile structures.

The system has an original and uncompromising design in terms of strength and reliability even if it adopts the world standard solution of the circular blade from 28 mm.

In terms of dimensions, the system is built following the dimensions requested by the customer, and moreover it can be adapted or accessorised according to needs.

An Italian project that makes the most of Italian materials and technologies to enhance national skills and reduce production and maintenance costs.

There is also the version of the double-headed plotter cutter with circular blade plus tangential blade which is used by upholsterers to make smaller and more accurate geometries given the scalpel shape of the second tangential blade..

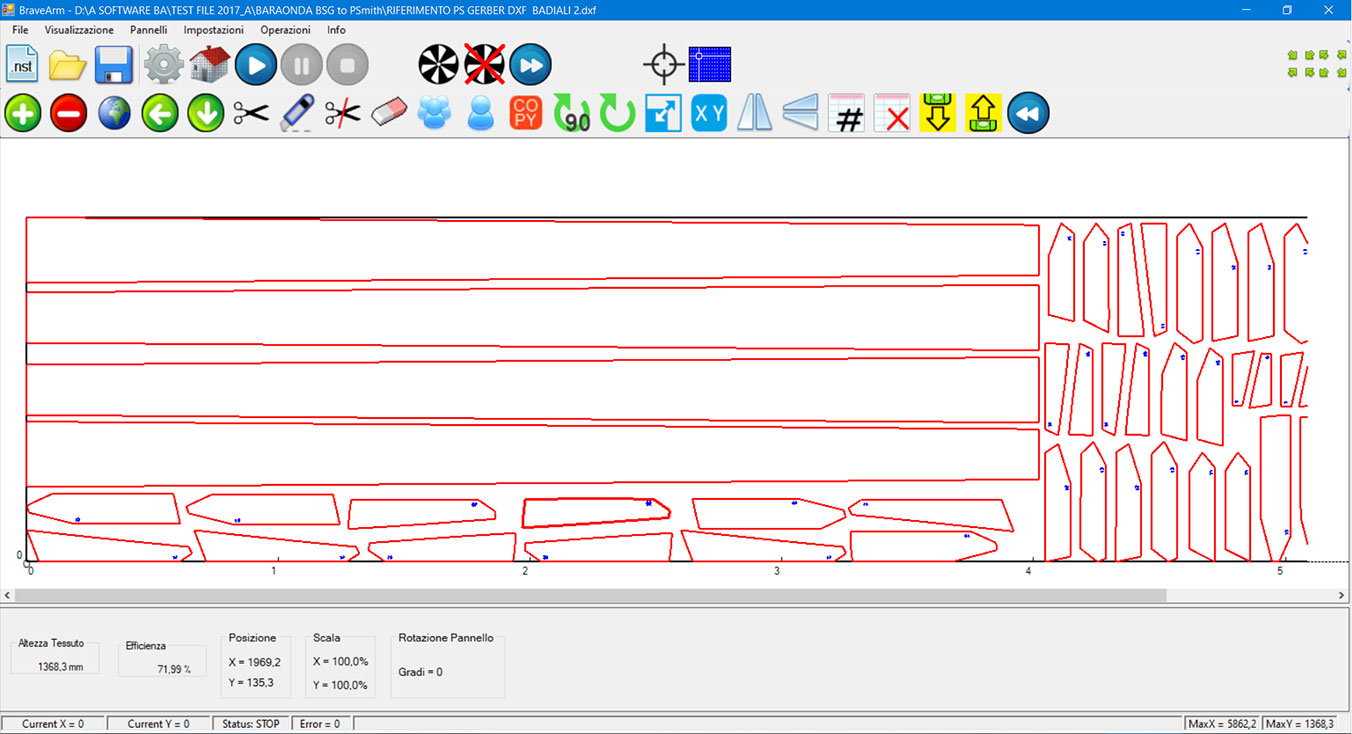

The program that interfaces the operator and guides the system was also created internally and finally speaks Italian; in this way the possibility of customization is also extended on the software side, and the response time to customer requests is improved.

The format of the drawings accepted by the system is DXF which has maximum diffusion and portability characteristics and is not tied to a particular proprietary format.

For the work in the sail loft it is possible to import drawings from the main sail design programs.

General features

● Custom workspace size

● Arm width up to 5,5 meters

● Universal pneumatic pen holder

● Circular blade diam 28 mm (standard)

● Tangential carbide blade (optional)

● Adjustable cutting pressure (2-7 bar).

● High thickness cutting capacity

● Software in 4 languages

● DXF drawing format (std)

● Drawing format for sailmakers : all

● Nesting with mouse / keyboard

● Setting of machining sequence

● Digitizer (optional)

● Vacuum table calpestabile

● Vacuum table in aluminum profile

● Minimum maintenance

● Reduced operating costs

● System with CE marking

● Highly competitive price

Technical features

► Maximum speed 1000 mm/s

► Position accuracy max 0,25 mm

► Hybrid step motors with high torque and efficiency

► Motor drivers with microstep control

► Linear guides with technopolymer shoes

► Blade holder with bearings for the circular blade

► Adjustable cutting pressure.

► Suction force up to 4,0 Kg/dm2

Requested services

► Electrical panel plotter-cutter 800W @ 220VAC Dimensions 40x20x65h cm

► Vacuum pump 3,0 – 5,5 Kw @ 380VAC

► Compressed air 6-8 bar; consumption <8 liters/min